MATRIX ELECTRICAL WIRING SYSTEMS

The MATRIX electrical wiring system is designed to significantly simplify and reduce the overall cost to wire integral pulse valve solenoid coils to timers, controllers or terminal blocks. The MATRIX is a pre-wired harness specifically manufactured and provided per customer requirements which includes the number of exits (valves) and pitch (pulse valve center to center distance) to fit coils with standard DIN connections. One Matrix harness can support up to fifteen (15) integral pulse valves. For arrangements requiring more than fifteen (15) integral pulse valves, multiple Matrix harnesses can be combined as required to provide Matrix connectors to all pulse valves on the header.

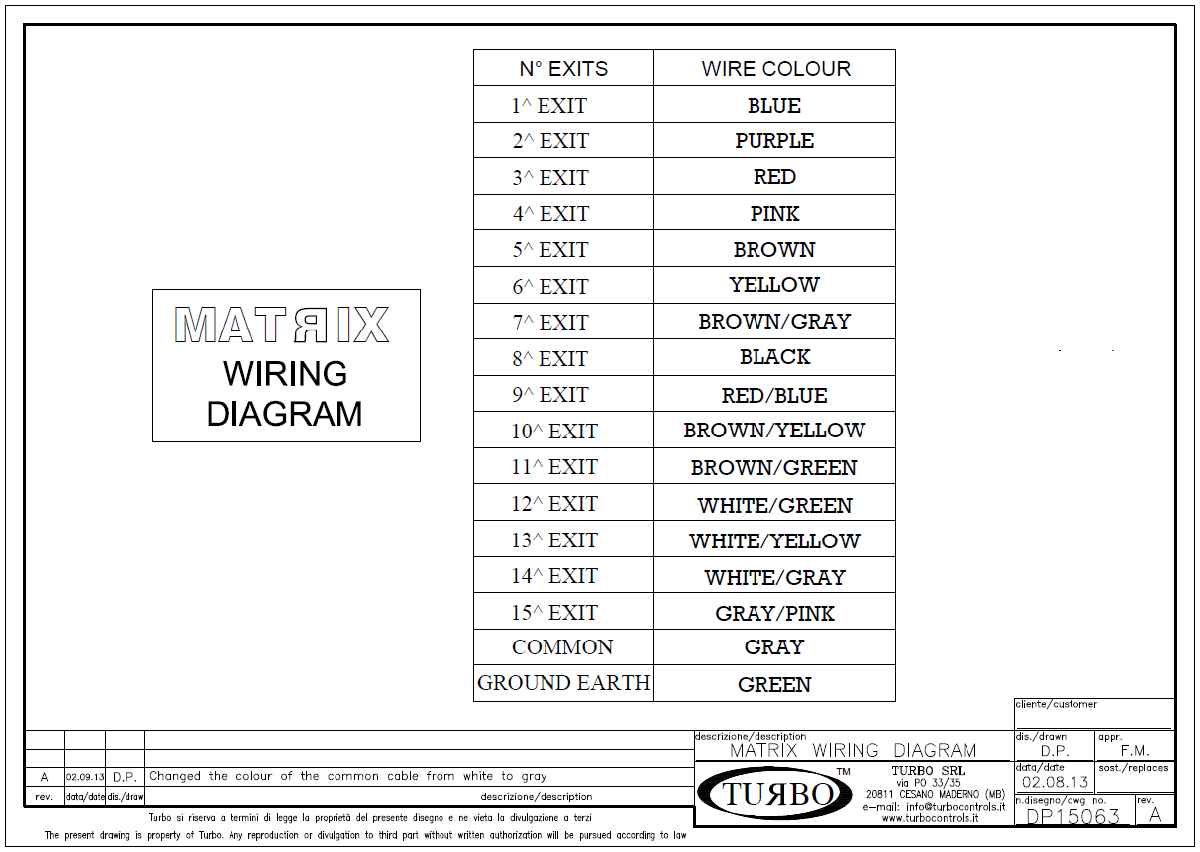

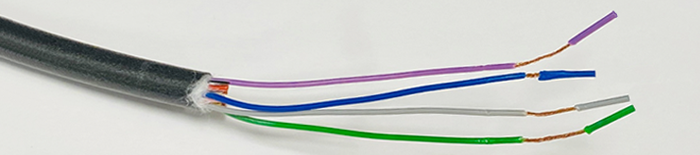

The free wire end of the MATRIX cable where a timer, controller or other terminal blocks come pre-stripped with color coded conductors to land on the electrical terminals as required.

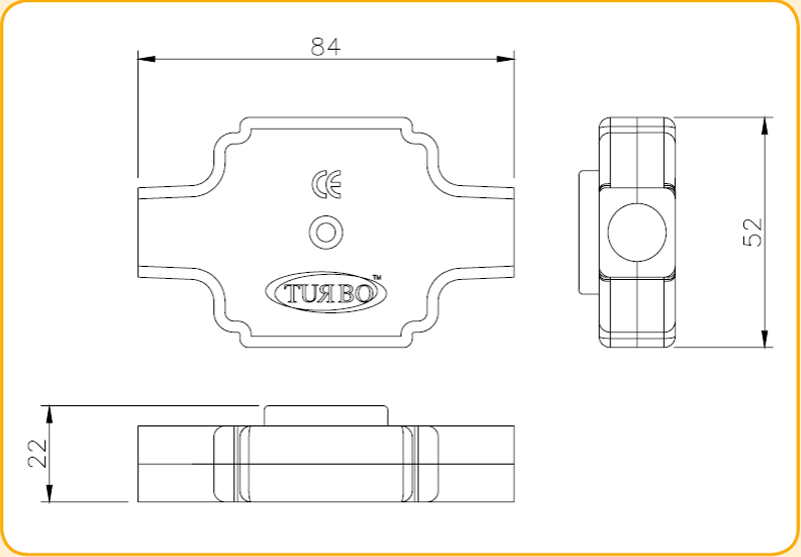

The compact Matrix connector that is inserted onto the blades and fastened to the coil at each valve.

PRODUCT OVERVIEW

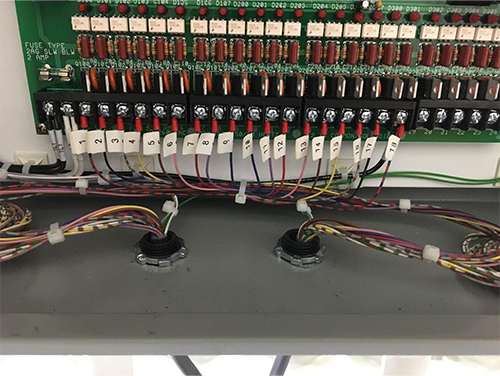

The photos below show actual Matrix electrical wiring system installations:

Matrix electrical wiring systems can be supplied from the simplest of systems to the most complex. Royal United stands ready to help configure and supply the exact system per your unique requirements!